After-Sales Service Tel: +86-315-5092270

冀ICP备18025041号 Powered by 300.cn Tangshan SHINDA(TangShan) CREATIVE OIL&GAS EQUIPMENT CO., LTD.

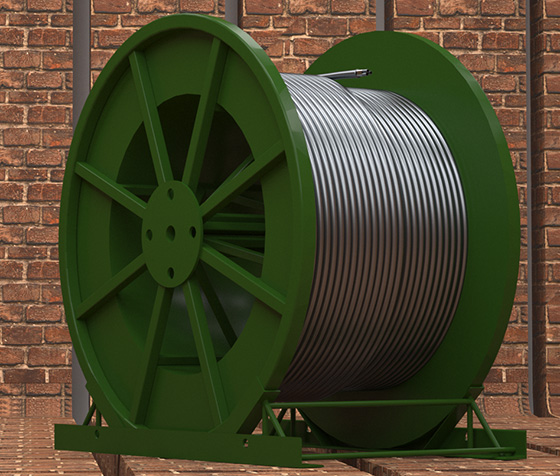

How to maintain quality ST80 Coiled Tubing

quality ST80 Coiled Tubing, as an integral part of automation equipment, plays a key role. Therefore, correct maintenance methods can help prolong the service life of quality ST80 Coiled Tubing and improve the production efficiency of the equipment. The following will take the maintenance of quality ST80 Coiled Tubing as the theme, and introduce how to maintain it correctly.

1. Regular inspection and cleaning

First of all, before using quality ST80 Coiled Tubing, you need to check it regularly to ensure that it is in normal operation. During the inspection process, special attention should be paid to whether the connecting parts are loose, whether there is any abnormal sound, etc. If there is a problem in the inspection, it is necessary to apply for replacement of the faulty parts in time, and carry out cleaning and maintenance.

2. Maintenance of lubrication mechanism

quality ST80 Coiled Tubing requires friction and wear during operation, and proper lubrication will affect its working stability and life. Therefore, the lubrication mechanism is the most important part of quality ST80 Coiled Tubing maintenance. For the lubricating mechanism, lubricating oil or grease needs to be added according to the specified time intervals to ensure that it is always in a normal operating state.

3. Protective measures

Some working environments are harsh, and some additional maintenance measures are required to ensure the stable operation of quality ST80 Coiled Tubing. For example, the quality ST80 Coiled Tubing working in a humid environment needs to be inspected for humidity, and dried in time to prevent corrosion, prevent rust, etc.

4. Troubleshooting

During the maintenance process, if there is a failure, it needs to be dealt with in time. Generally speaking, small faults can be handled by operators or maintenance personnel. However, for more complex and dangerous faults, it is recommended to ask specialists to handle them.

The above is the basic method of quality ST80 Coiled Tubing maintenance. Correct maintenance can improve the operating efficiency of the equipment, prolong its service life and reduce maintenance costs. When using quality ST80 Coiled Tubing, please be sure to abide by the relevant safety regulations, and formulate a reasonable maintenance plan based on specific conditions.