After-Sales Service Tel: +86-315-5092270

冀ICP备18025041号 Powered by 300.cn Tangshan SHINDA(TangShan) CREATIVE OIL&GAS EQUIPMENT CO., LTD.

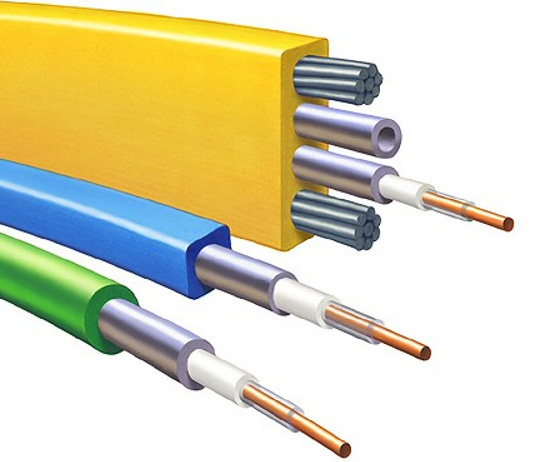

Several components of Tubing Encapsulated Cable

1. Conductive wire core: made of high conductivity material (copper or aluminum). According to the requirements of the softness of the Tubing Encapsulated Cable under the laying conditions, each core may be formed by twisting a single wire or multiple wires.

2. Insulation layer: The insulation material used for Tubing Encapsulated Cable should have high insulation resistance. Insulating materials commonly used in Tubing Encapsulated Cable include oil-impregnated paper, polyvinyl chloride, polyethylene, cross-linked polyethylene, rubber, etc.

3. Sealing sheath: protect the insulated wire core from mechanical, moisture, moisture, chemicals, light, etc. damage. For insulation susceptible to moisture, lead or aluminum extruded hermetic seals are generally used.

4. Protective cover layer: used to protect the sealing sheath from mechanical damage. Generally, galvanized steel strip, steel wire or copper strip, copper wire, etc. are used as armor to wrap around the sheath (called armored Tubing Encapsulated Cable). The armor layer also plays the role of electric field shielding and preventing external electromagnetic wave interference. In order to prevent the steel belt and steel wire from being corroded by the surrounding medium, they are generally coated with asphalt or wrapped with a dipped jute layer or extruded polyethylene or polyvinyl chloride sleeve.