After-Sales Service Tel: +86-315-5092270

冀ICP备18025041号 Powered by 300.cn Tangshan SHINDA(TangShan) CREATIVE OIL&GAS EQUIPMENT CO., LTD.

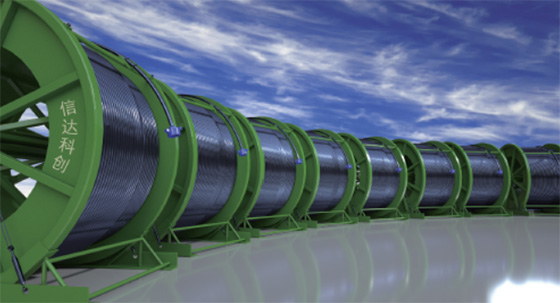

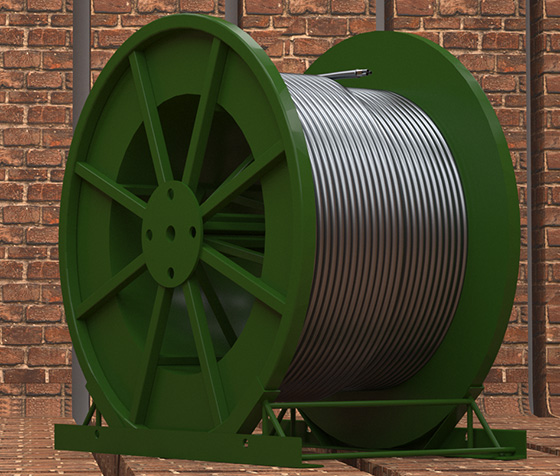

Coiled Tubing

Coiled Tubing

Coiled tubing is a jointless tubing formed by welding several sections of flexible tubing with a length of more than 100 meters through butt welding or inclined welding. The length of coiled tubing is generally up to several hundred meters to several kilometers. It can be wound on a reel and used for specific downhole operations such as workover, drilling, perforation, stimulation, well completion, and logging. For applications in acidic environments, our company has developed high-chromium corrosion-resistant alloy coiled tubing and titanium alloy coiled tubing.

Material:

Carbon Steel, CRA, Titanium Alloy

Data Sheet

| Material | ST70 | ST80 | ST90 | ST100 | ST110 | |

| Chemical Composition | Cmax | 0.16 | 0.16 | 0.16 | 0.16 | 0.16 |

| Mnmax | 1.20 | 1.20 | 1.20 | 1.65 | 1.65 | |

| Pmax | 0.025 | 0.020 | 0.020 | 0.025 | 0.025 | |

| Smax | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | |

| Simax | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | |

| Cr | ||||||

| Ni | ||||||

| Mo | ||||||

| Yield Strength(min),psig | 70,000 | 80,000 | 90,000 | 100,000 | 110,000 | |

| Yield Strength(max),psig | 80,000 | 90,000 | 100,000 | |||

| Tensile Strength(min),psig | 80,000 | 88,000 | 97,000 | 108,000 | 115,000 | |

| Hardness,HRC | 22 | 22 | 22 | 28 | 30 | |

| Flaring | The acceptable criterion is no cracking in the weld seam region or base metal up to a minimum ID expansion. | |||||

| Flattening | No cracks or breaks exceeding 0.125 in. (3.2 mm) in any direction in the weld or the parent metal shall occur on the outside surface until the distance between the plates is less than the value specified. | |||||

| Material | ST130 | ST316L- | ST13Cr- | ST2205- | ST2507- | |

| Chemical Composition | Cmax | 0.16 | 0.030 | 0.15 | 0.030 | 0.030 |

| Mnmax | 1.90 | 2.00 | 2.00 | 1.20 | ||

| Pmax | 0.025 | 0.045 | 0.120 | 0.030 | 0.035 | |

| Smax | 0.005 | 0.030 | 0.030 | 0.020 | 0.020 | |

| Simax | 0.50 | 0.75 | 1.00 | 0.80 | ||

| Cr | 16.0-18.0 | ≥11.5 | 22.0-23.0 | 24.0-26.0 | ||

| Ni | 10.0-14.0 | 4.5-6.5 | 6.0-8.0 | |||

| Mo | 2.00-3.00 | 3.0-3.5 | 3.0-5.0 | |||

| Yield Strength(min),psig | 130,000 | 40,000 | 80,000 | 80,000 | 90,000 | |

| Yield Strength(max),psig | ||||||

| Tensile Strength(min),psig | 135,000 | 70,000 | 88,000 | 95,000 | 116,000 | |

| Hardness,HRC | 36 | 200HV | 30 | 30 | 32 | |

| Flaring | The acceptable criterion is no cracking in the weld seam region or base metal up to a minimum ID expansion. | |||||

| Flattening | No cracks or breaks exceeding 0.125 in. (3.2 mm) in any direction in the weld or the parent metal shall occur on the outside surface until the distance between the plates is less than the value specified. | |||||