After-Sales Service Tel: +86-315-5092270

冀ICP备18025041号 Powered by 300.cn Tangshan SHINDA(TangShan) CREATIVE OIL&GAS EQUIPMENT CO., LTD.

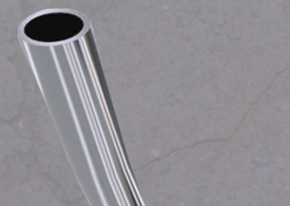

How to avoid the disadvantage of shrinkage cavity in Seamless Tubing in china

Since the shortening of seamless steel pipe precision casting greatly exceeds the shortening of cast iron, in order to avoid the shortcomings of shrinkage and shrinkage of Seamless Tubing in china steel pipes, risers, cold iron and subsidies are mostly used in the casting process to complete sequential condensation. In order to avoid shrinkage cavities, shrinkage holes, pores and cracks in Seamless Tubing in china steel pipe castings, Seamless Tubing in china steel pipes should have a uniform wall thickness, avoid sharp and right angle structures, add sawdust in the molding sand, and in the core Add coke. And use hollow sand cores and oil sand cores to improve the franchise and permeability of sand molds or sand cores.

Processing characteristics of Seamless Tubing in china castings: Due to the poor fluidity of molten steel, in order to avoid cold isolation and casting of Seamless Tubing in china castings, the wall thickness of steel castings should not be less than 8mm. Use dry casting or hot casting; appropriately increase the pouring temperature, generally 1520 ° ~ 1600 ° C, due to the high pouring temperature, the high degree of superheat and the long fluidity time of molten steel, the fluidity can be improved. Seamless Tubing in china reminds you that if the pouring temperature is too high, Seamless Tubing in china will cause defects such as coarse grains, hot cracks, pores and sand adhesion. Therefore, the casting temperature of usually smaller, thinner and messy shaped castings is about 150°C, the melting point of steel. The main reason why the conflict torque of the thick-walled seamless steel pipe decreases with the increase of the moving speed is the change of the smooth condition. When the object stops, the smooth oil between the two smooth surfaces is squeezed out, showing a dry conflict or a near-dry conflict, until the speed increases to point 3, it turns into a wet conflict, and an oil film is established between two metal surfaces. At the moment of conflict, it is separated by oil molecules, showing positive damping characteristics, which can prevent objects from vibrating at high speed.